Our website has moved! Please visit smart-move.ca

April 17, 2024

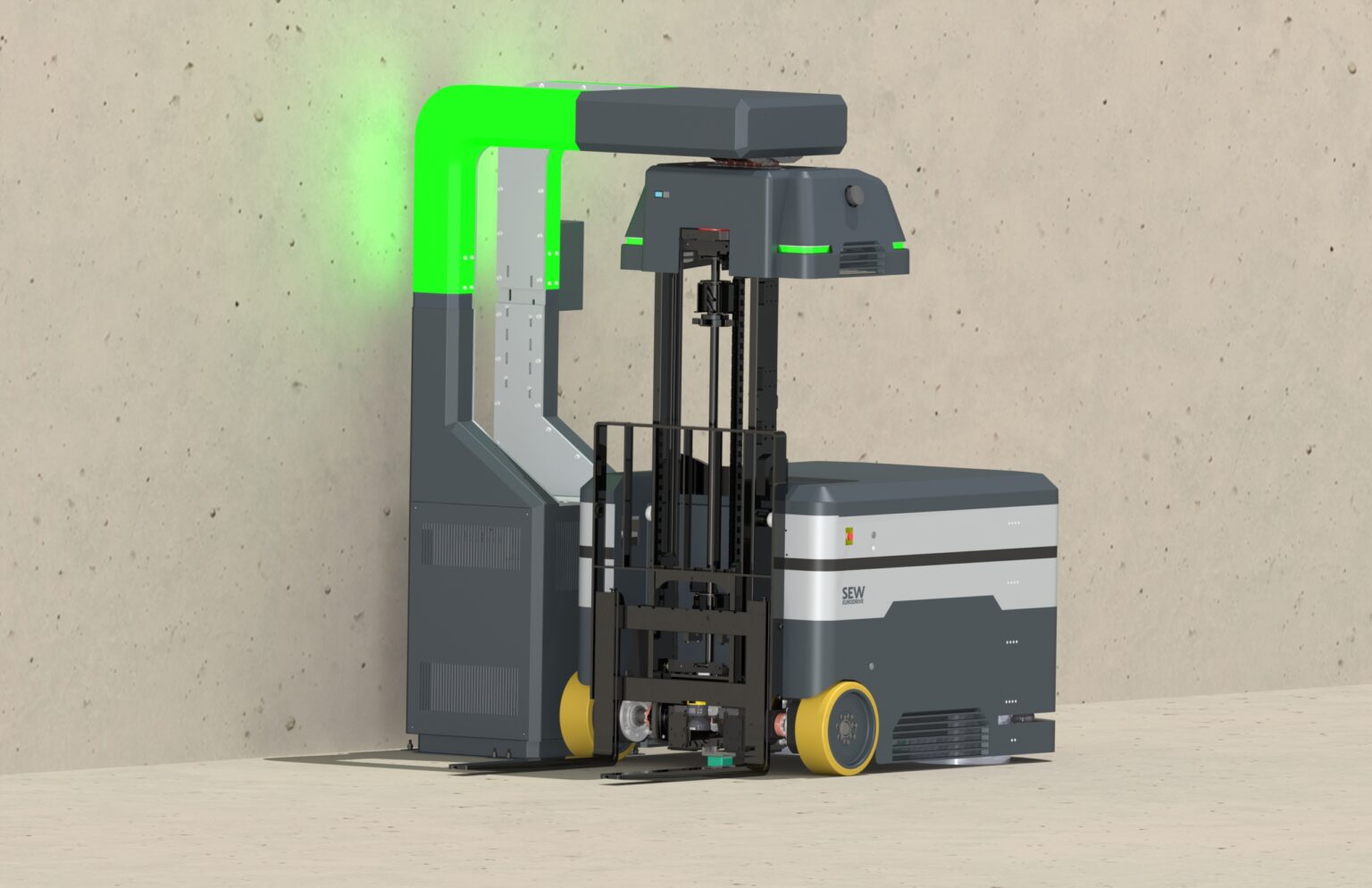

Solving motion control problems has always been SEW-Eurodrive’s primary focus. “Inspiration for our ideas comes from our customers,” says Brendan Daniels, Chief Design Engineer. “When we are onsite at a clients’ facility, they may unwillingly discuss problems that, in their opinion, are unsolvable. That’s what motivates us to innovate and find a solution”. environments already have their share of harmful emissions. As a result, many plants are looking for new ways of reducing airborne toxins and creating a safer work environment without sacrificing equipment performance or productivity.

March 1, 2023

Moving 68 Ton metal coils within a warehouse space requires raw power. Historically, this was only achievable by using large payload RGVs (Rail Guided Vehicles) with polluting combustion engines or environmentally damaging lead acid batteries.

Factory and warehouse environments already have their share of harmful emissions. As a result, many plants are looking for new ways of reducing airborne toxins and creating a safer work environment without sacrificing equipment performance or productivity.

March 24 2023

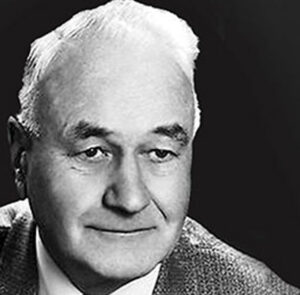

Anthony Peluso-Vice President & COO, SEW-EURODRIVE Canada, and Lyall Watson-Manager of Sales, cap off a one and half hour facility tour with Hubertus Heil, The Federal Minister of Labour and Social Affairs of Germany. Following his visit at SEW-EURODRIVE, the Minister is scheduled to tour SEW-EURODRIVE’s Educational Partner, the Barrett Centre for Technology Innovation (Barrett CTI) Located at Humber College’s North Campus. In 2018, SEW-EURODRIVE and Humber College entered into a five-year partnership agreement designed to build awareness and provide training and applied research opportunities related to Industry 4.0 technologies, a critical aspect of advanced manufacturing.

June 01, 2022

It’s funny how history repeats itself—always reemerging with the same premise, but adapting to what is relevant at the time. In the 1960s and 70s, milk and other perishables were delivered straight to our doors, and then one day, the service just vanished. Today, delivery of groceries (or anything, for that matter) transcends in-store sales. Predicting how the market is going to react to new ideas certainly isn’t easy; even with sophisticated forecasts, AI analytics, and algorithms, as we all have learned, there’s never a 100% guarantee. But what about the people who created the products we didn’t even know we wanted, all based on a hunch? That is pure brilliance!

March 01, 2021

Digital technologies are increasingly being customized to serve the needs across multiple industries with maximum application being witnessed in automotive, healthcare, aerospace and defense, chemical and consumer goods.

The automotive industry is witnessing rapid digital adoption with benefits including faster time-to-market and lower costs. The A&D industry has one of the highest rates of digital adoption owing to the sheer complexity of its value chain. Digitalization in healthcare is centered around medical devices and pharmaceuticals. Even though, the chemical and consumer goods industries are late bloomers, they are now not only transforming production but also creating smart supply chains and new business models.

Focus on growing your business, and let us deal with the integration of Smart Technology. Get ready for the MAXOLUTION® All-in-one Solution and make the shift to an intelligent, highly efficient, advanced manufacturing process that is industry 4.0 ready!