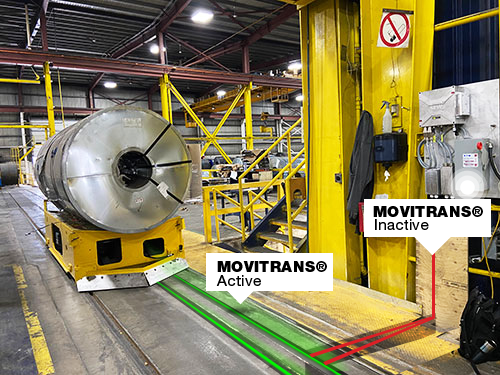

By now, most of us are familiar with the benefits of integrating Autonomous Guided Vehicles into motion control plans. AGVs play a vital role in systemizing and automating throughput in various industries, specifically those with integrated end-to-end load-handling systems, allowing AGVs to run continuously.

Solving motion control problems has always been SEW-Eurodrive’s primary focus. “Inspiration for our ideas comes from our customers,” says Brendan Daniels, Chief Design Engineer. “When we are onsite at a clients’ facility, they may unwillingly discuss problems that, in their opinion, are unsolvable. That’s what motivates us to innovate and find a solution”.

The fundamental design principles of an AGV are to autonomously shuttle payloads across a factory or warehouse setting with little or no human intervention. However, AGVs have limitations, specifically when palletized payloads are in the final stages of throughput, usually riding along on a conveyor system ready to be lifted and loaded into a trailer.

NEXT: Strategy and Ideation.

That’s where the Automated Guided Forklift (AGF) comes into play! SEW’s MAXOLUTION® Team of Engineers is in the prototype and early testing phases of its fully automated forklift, capable of lifting, shuttling, and dropping pallets anywhere in a factory or warehouse setting without human intervention.

The most notable difference between an AGF and a traditional AGV is the AGF’s ability to lift and place pallets from one elevation to another, eliminating the need for additional load-handling applications.

The design intent is to systemize payload handling, improve overall safety, and allow businesses the flexibility to custom-create and quickly revise virtual payload motion plans with minimal interruptions or effort.

NEXT: Target Performace Specifications.