the

problem

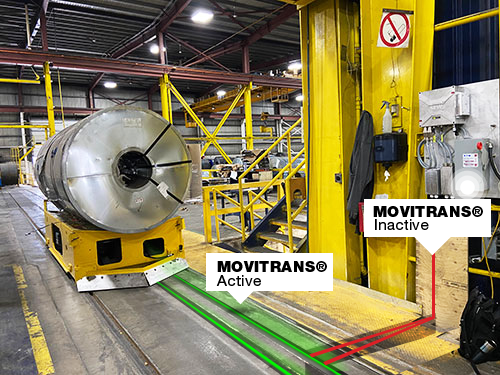

Moving 68 Ton metal coils within a warehouse space requires raw power. Historically, this was only achievable by using large payload RGVs (Rail Guided Vehicles) with polluting combustion engines or environmentally damaging lead acid batteries.

Factory and warehouse environments already have their share of harmful emissions. As a result, many plants are looking for new ways of reducing airborne toxins and creating a safer work environment without sacrificing equipment performance or productivity.